Ordinary lathe: Lathe is mainly used to process shafts, discs, sleeves and other workpieces with rotating surfaces. It is the most widely used type of machine tool processing in machinery manufacturing. (Achievable accuracy 0.01mm)

Ordinary milling machine: It can process planes, grooves, various curved surfaces, gears, etc., and can also process more complex profiles. (Achievable accuracy 0.05mm)

Grinder: A grinder is a machine tool that grinds the surface of a workpiece. (Achievable accuracy 0.005mm, small parts can achieve 0.002mm)

CNC lathes mainly process batch products, high-precision parts, etc. (Achievable accuracy 0.01mm)

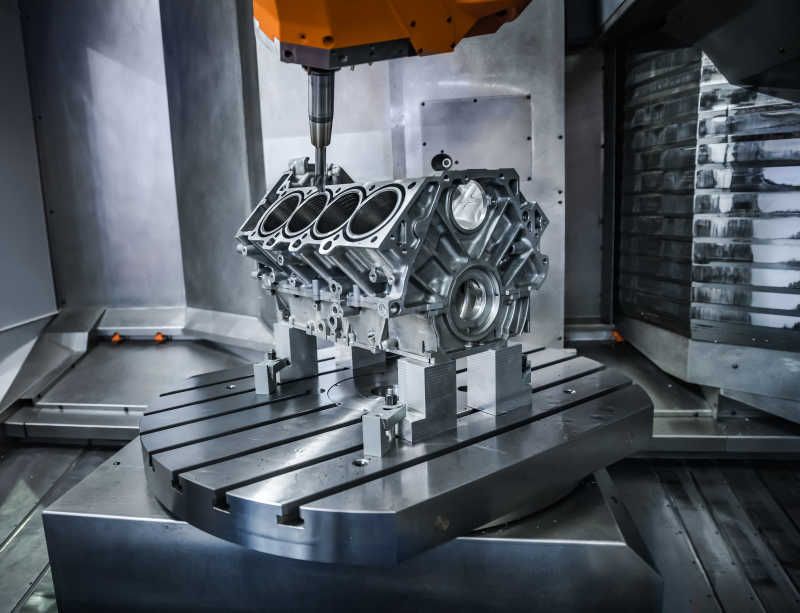

CNC milling machines mainly process batch products, high-precision parts, complex parts, large workpieces, etc. (Achievable accuracy 0.01mm)

Wire cutting

The electrode used for the slow wire is brass wire, and the middle wire is molybdenum wire. Slow wire processing has high precision and good surface finish. Process some fine holes, fine grooves, etc. (Slow wire traveling can achieve an accuracy of 0.003mm, medium wire traveling can achieve an accuracy of 0.02mm)

Spark machine

EDM can process materials and complex-shaped workpieces that are difficult to cut with ordinary cutting methods, and is not affected by material hardness or heat treatment conditions. (Achievable accuracy 0.005mm)